|

JiaXing MT Stainless Steel Co., Ltd

|

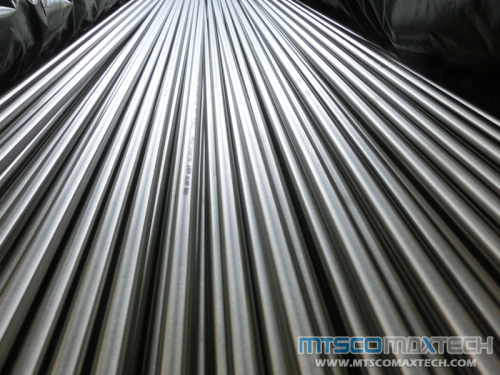

TP317L ASTM A213 SEAMLESS BA TUBE

| Price: | 6.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Better mechanical property

1. Process Method: Cold Drawn, Cold Rolled

2. Surface Finish: Bright Annealed

3. Materials: TP304/L/H; TP316/L/Ti; TP309S; TP310S; TP321/H; TP317L; TP347/H, etc

4. Ends: Beveled or Plain

5.Standards: ASTM A213/ASME SA213, ASTM A269/ASME SA269, EN10216-5, JIS G3463, etc

6. Size Range:

OD: (6.35mm-44.5mm)

WT: (0.71mm-3.05mm)

7. Tolerances: according to the specification or customer's request and drawings

8. Applications: instrument tubing, chromatography tubing, hydraulic tubing, high pressure tubing, cleaned tubing, heat exchanger, etc

9. Inspection: PMI test, Hydraulic Test, Eddy Current Test, Non-Destructive Test, etc

10. Advantages:

Better mechanical property

Perfect inspection method and inspection equipment

Related Search

Astm Seamless Tube

Astm A106 Seamless Tube

Astm Seamless Pipe

Astm A53 Seamless Pipe

Astm A500 Steel Tube

Astm B338 Titanium Tube

More>>